Solutions

Build 5G

We converge fragmented instruments into a shared, automated, early‑warning platform that lowers CapEx, reduces retests, accelerates release cycles, and scales cleanly to new technologies.

Drivers for Change: Waste in the Old Testing Model

Legacy approach = single instrument silos + manual queues + late patching. Result: idle capital, engineer waiting time, fragmented models, rising maintenance, and hard-to-defend budgets. After two decades in test & optimization, our mandate is clear: cut wrong purchases, lift utilization, surface risk earlier, and convert testing from reactive spend to proactive value creation.

Shared Capability Pool: From Buying Hardware to Calling Scenarios

We pool RF analysis, protocol compliance, multi‑UE concurrency, service experience, energy/power, EMF compliance, slicing, and security tests behind one entry point. One data acquisition yields multiple outputs (performance + energy + compliance). Nightly automated regressions free daytime engineers. Typical impact: utilization rises from ~40% to 60–70%, queues shrink, duplicate outsourcing/manual spot‑checks decline sharply.

Lowering Acquisition Cost: Layered Configuration + On‑Demand Rental + Digital Ledger

We classify capabilities into: (a) high‑frequency essentials (own/pool), (b) high‑cost low‑frequency (rent/time-slice). Expensive modules (ultra‑wide BW, mmWave OTA, large channel/multipath emulation) are spun up only when needed. A live instrument ledger tracks utilization, warm‑up/calibration overhead, software option usage, energy draw, and redeployment opportunities. Script reuse + automation strips “write-from-scratch” labor. All avoided hours, reduced retests, and accelerated launches become auditable ROI entries.

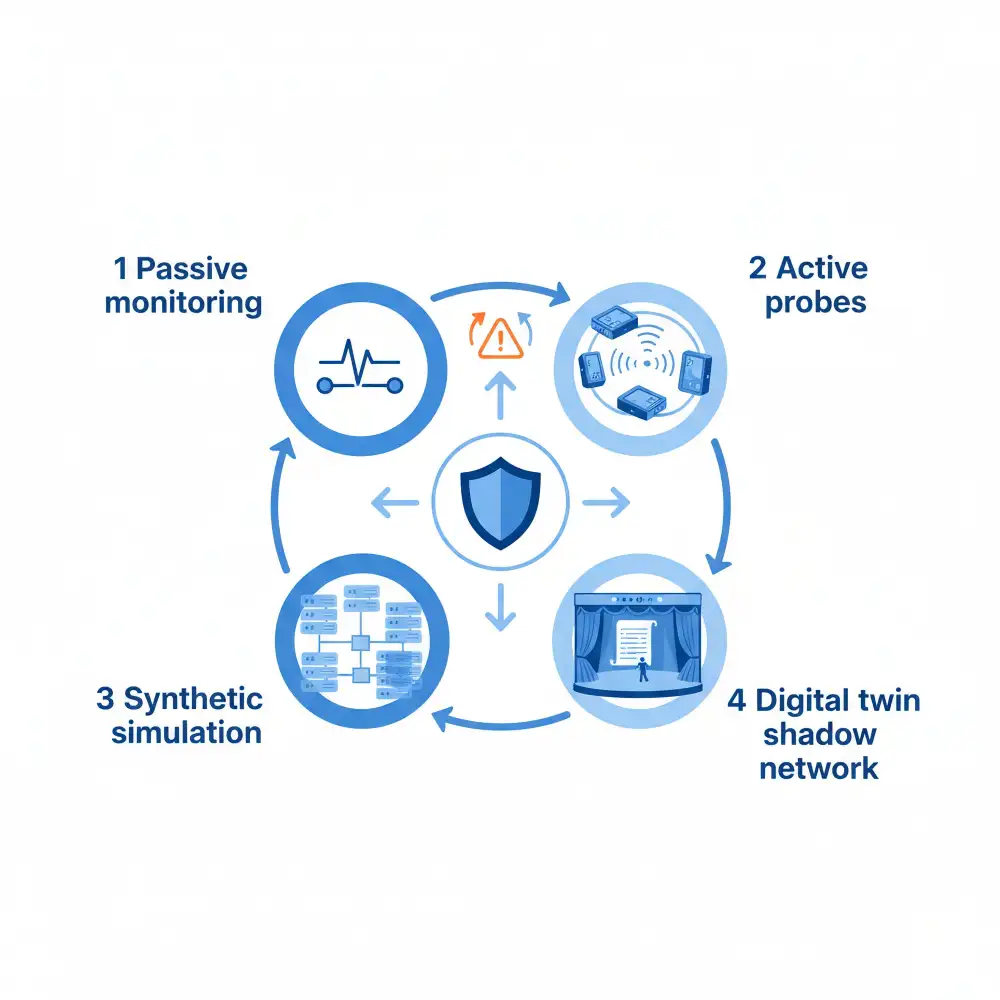

Quality & Experience Assurance: A Four-Step Early Warning Method

Shift from a “fix after complaint” stance to proactive prediction by layering Passive Monitoring for continuous health baselines, Active Probes that execute scheduled synthetic transactions, Synthetic Simulation to rehearse high‑value or failure‑prone paths under controlled low load, and a Digital Twin that safely trials parameter or configuration changes before they reach production. In practice, you validate uplink scheduling adjustments inside the twin first, while XR or high‑bitrate video waveform and pattern models flag degradation trends before users feel impact—resulting in fewer escalations, reduced rework, and earlier interception of defects.

Smooth Future Expansion: No Rip-and-Replace

RedCap, massive IoT concurrency, XR latency, uplink boosts, dynamic spectrum, satellite/non-terrestrial integration, AI self-optimization—each added via modules and script updates, not forklift rebuild. We continually ingest standards, white papers, and regulatory changes, distilling them into executable templates and KPI checklists—removing time spent parsing dense documentation. Platform becomes an upgradable base layer, extending with business growth.

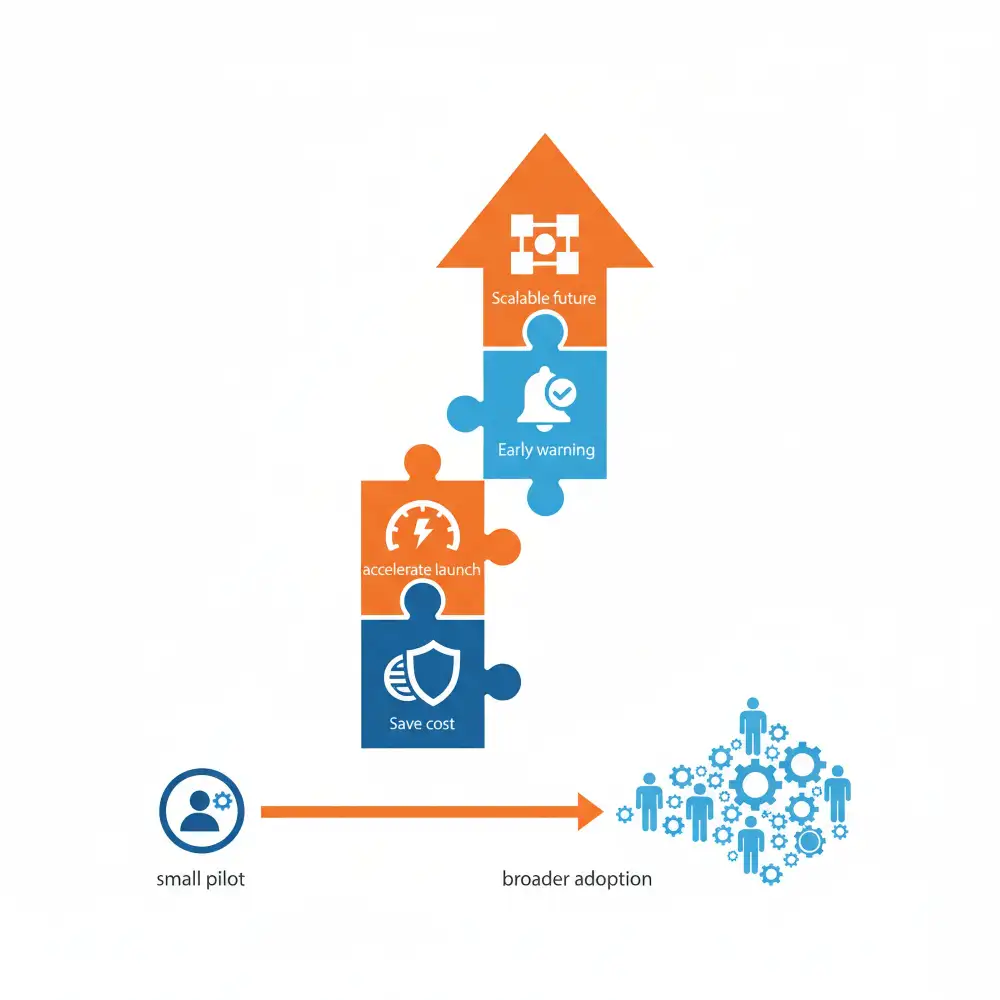

One-Line Value: Turn Testing into a Tool for Saving, Speed, Stability, and Scalability

Deliverables: higher utilization (fewer idle purchases), faster launch (automation + off-hour regression), earlier risk detection (probes + twin), frictionless expansion (modular growth), transparent ROI (ledger). Start with a focused 3‑month pilot (e.g., slice SLA, RedCap trial, XR experience, energy optimization, or EMF compliance automation). Quantify time saved, rework reduction, cost avoidance—then scale with confidence.

Product Recommendations

View All